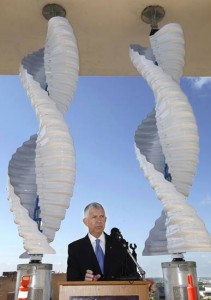

The Oklahoma Medical Research Foundation (OMRF) is doing its part to help reduce heavy use of electricity. The facility hired SWG Energy Inc. out of Dallas,TX, to install 18 vertical axis wind turbines on top of their 130 foot tall research tower. The 18 turbines are installed in three parallel rows and have a specially designed hood mounted over them.

The Oklahoma Medical Research Foundation (OMRF) is doing its part to help reduce heavy use of electricity. The facility hired SWG Energy Inc. out of Dallas,TX, to install 18 vertical axis wind turbines on top of their 130 foot tall research tower. The 18 turbines are installed in three parallel rows and have a specially designed hood mounted over them.

“One of the reasons we chose these particular turbines is because they are designed to generate less noise and vibration than windmill-type turbines,” said engineer and consultant Sheryl Rood. “But before we went ahead with the entire installation, we wanted to test for ourselves.”

SWG Energy Inc. began work on installing the Venger Wind Model 2 wind turbines that consist of a mixture of aluminum and steel. They are heavy enough to withstand the typical Oklahoma weather, yet light enough to use the maximum amount of wind power possible. These 4.5 kilowatt turbines will turn out approximately 85,500 kilowatt hours of energy per year, enough to power seven average homes. The created energy is released directly into the tower’s grid. The system is designed so that wind power is used as first priority but, if necessary, it switches to OG+E power.

On June 19, 2012, a ceremony was held on top of the tower and, as the wind whipped by at 30 mph, OMRF President Stephen Prescott, M.D., and Oklahoma Supreme Court Chief Justice Steven Taylor flipped the switch to begin a new era of energy conservation.

[youtube]http://www.youtube.com/watch?v=l_6GG1pQ9Gg[/youtube]

The installation of the turbines also made OMRF the first medical research facility in the US to use wind-powered energy.

Vertical axis wind turbines (VAWT) are becoming popular as more companies look to reduce their dependence on the grid. VAWTs help reduce the ever-increasing, high energy costs for companies like the Oklahoma Medical Research Foundation that use a heavy amount of energy.

For more information about Venger Wind, click here.